CORTS® Mill Refurbishment

Performance Requirements

Over time, chock and housing surfaces can sustain damage resulting from wear, corrosion and hammering. While flat bearings and lubrication are meant to protect against these dangers, improper flat bearing materials, improper lubrication as well as years of production can result in surface damages that require expert machining to repair.

Left uncorrected the damaged mounting surfaces can lead to even more damage. Bearings cannot be mounted flush resulting in uneven impact and wear protection, corrosion from water seeping behind the bearings and an increased or uneven gap which hinders proper lubrication and roll position. This dramatically reduces overall production quality.

The Resolution

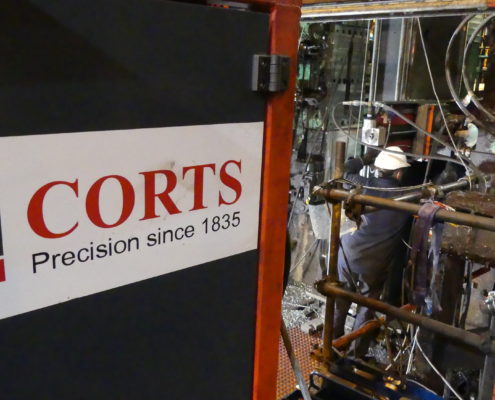

CORTS® Engineering has extensive experience in correcting multiple types of problems through precision reconditioning of surfaces. A team of trained experts uses custom designed milling machinery to accomplish reconditioning tasks quickly, accurately and efficiently.

These efforts will return the highly precise mounting surfaces and productions windows to a minimum of OEM standards while often exceeding them. CORTS® Engineering’s experience runs the compete range of mill types with the ability to easily adapt to the requirements of each individual site and situation.

Magnetic Drilling Machine

Drilling of Diameters from 10 mm to 40 mm

Thread Cutting from M 5 to M 36

Special Drilling Machine BF 25

Drilling up to D 50 mm, Mirroring of Flat Surfaces up to D 270 mm

Thread Cutting from M 20 to M 48

Machine types 3 – 8

ACF 5000

Milling of Rolling Mill Stands, Presses, etc., including use of two independent milling units simultaneously

Width ca. 2000 mm x Height ca. 5000 mm

Individual Specification

We have state-of-the art, partly CNC-controlled, mobile machinery at our disposal. Work can be carried out on your mill stands and chocks at your premises under top workshop conditions.

CORTS® has in-depth knowledge and experience with the milling and refurbishment of reference and mounting surfaces of mill housings and chocks based on over 90 years of customer care for precision linear bearings around the world. This refurbishment concept is the only way to control the gap between housing and chocks for years to come.